SUPERCAN

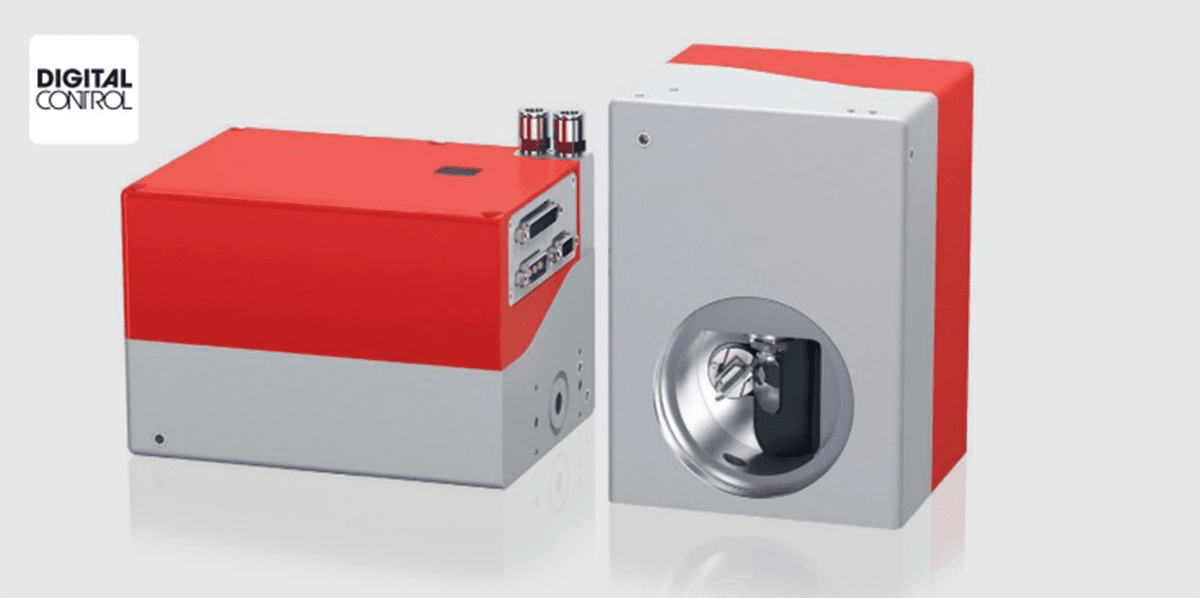

SUPERCAN IV

YOUR BENEFITS

The SUPERSCAN IV‘s model-based, digital regulation offers extremely dynamic responses and final speeds, which really come into play when used in MOTF-applications

(Marking-and-processing-On-The-Fly) in conjunction with one of our linear translator modules. The robust, water-cooled master block design, combined with optional air flushing,

enables applications at up to 6 kW laser power.

CONFIGURABLE THROUGH AND THROUGH

Lenses, protective glass, and mirror substrates and coatings are available for all standard laser types, wavelengths, light densities, focal lengths and processing areas. The control electronics were designed to be flexible to enable the configuration of additional sets of control parameters (tuning options). We would be happy to provide a customized configuration of the SUPERSCAN IV for your application.

TYPICAL APPLICATIONS

SUPERSCAN IV is ideally suited for these high speed applications:

- Scribing

- Perforation and cutting of plastic sheets and paper webs in the packaging industry

- Marking of electronic components

SUPERCAN V

YOUR BENEFITS

A fully digital feedback control electronics inside the SUPERSCAN V provides excellent dynamics and continuous monitoring of e.g. the position of the mirrors and their speed.

Depending on the applied protocol (SL2-100 or XY2-100), the mirrors can be positioned wit a resolution of up to 20 bits. Thanks to the enormous acceleration and maximum speed

of the digital galvanometers, the SUPERSCAN V performs also laser jobs with sharp edges extremely fast and precise.

CONFIGURABLE IN AND OUT

The lenses and lightweight SiC mirrors are suited for all common laser types, wavelengths, power levels, focal distances and working fields.

The control electronics can also support additional set of control parameters (tuning options).

We would also be happy to help you put together the perfect configuration for your application.

TYPICAL APPLICATIONS

SUPERSCAN V is ideally suited for these high end applications:

- Marking

- Welding

- Drilling or structuring of semiconductor wafers, medical products and security features of documents and chip cards

AXIALSCAN

Pre-focusing deflection units are developed due to cost and size limitations on the output lens and the beam aperture limitations with 2-axis deflection units,

which limit their ability to produce smaller spot sizes over medium size scanning fields. Pre-focusing deflection units meet customers application

requirements for large processing fields with smaller spot sizes and allow the user to change the working distance, field and spot size with the same deflection

unit. 3-axis technology also benefits application-on-the-fly with moving targets, while in 3D-applications, the setup enables processing of

non-flat parts or

uneven surfaces and high power products. These solutions are now available for Nd:YAG, diode, and CO2-lasers.

FUNCTIONAL DESCRIPTION

In a pre-focusing deflection unit, the laser beam first enters a moving lens - the Linear-Translator-Module.

A moving lens diverges the beam rapidly before it passes one or two focusing lenses. Then the beam hits a deflection unit that directs the laser

towards any X-Y position inside the marking field.

In a deflection unit without focus correction, the focused laser spot at the centre of the field describes an arc when moved in either axis,

creating a sphere of focused points above the working field. At locations away from the centre of the working field, the laser beam is not focused.

This is due to the increased length from the lens to the workpiece, as the scanners direct the beam away from the centre of the field.

In a pre-focusing deflection unit, focus compensation is accomplished by slight adjustments in the distance between the moving lens and

the focusing lens, as the scanners direct the beam across the working field by a third moving Z-axis,

hence the name “pre-focusing deflection unit”.

AM-MODULE NEXT GEN

Universal laser module for additive

manufacturing

AXIALSCAN-20/-30

Very small spot diameters at large field sizes

with high scanning speed.

Variable field sizes from 100 mm x 100 mm to

1,800 mm x 1,800 mm

AXIALSCAN-30 DIGITAL II

Digital control for very small spot diameters at

large field sizes.

Variable field sizes from 100 mm x 100 mm to

1,800 mm x 1,800 mm

AXIALSCAN-30 DIGITAL II HP

Digital control with small spot sizes for large

working field and laser power up to 4 kW.

Variable field sizes from 200 mm x 200 mm to

1,200 mm x 1,200 mm

AXIALSCAN FIBER-20/30

Pre-focusing-unit for pre-adjustable processing

field sizes from 250 mm x 250 mm to

900 mm x 900 mm

AXIALSCAN-50 DIGITAL II

Cutting-edge digital control electronics offers

smallest spot diameters at large working fields.

Variable field sizes from 300 mm x 300 mm to

1,000 mm x 1,000 mm

AXIALSCAN FIBER-50

Many laser beam deflection units can weld and cut – but only a handful can do so “on the fly”.

The AXIALSCAN FIBER-50 (AS F-50) ensures that the laser process is highly dynamic and precise, even when the workpiece is passing under

the deflection unit at varying speed.